01

Raw Material

Since the start, the factories we Utmedical chose to cooperate with have been insisting on independent producton including the sould manufacture chain from design, molding, stamping, injection molding and Production to packaging and transpor. A streamlined manufacture in each single factory can promise customers a full control over product quality and cost's saving.

Our Manufacturing Partners also have various tooling machine and facilities to support the production line all stages of design and manufacture, from concept to finish, in a highly focused effort to bring industry lever products and service to you.We design our new products by using advanced skills and innovative processes which are developed by our R& D team. At the product design phase, equipment engineers and manufacturing staff discuss frequently the overall features of our products and figure out the most optimal process for each of products. To sum up, we have developed our products and manufacturing equipments through integration of production processes which also become the success key for us to achieve efficient and mass production.

Raw Material

Cutting

CNC Stamping Lathe Punching

CNC Bending

Drilling Hole

Welding

Sewing

Assembly

Finshed Product Inspection

Package and Store

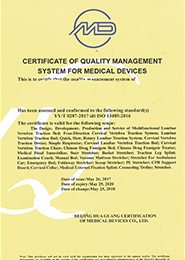

To gain access to markets with the most rigorous standards for medical devices and medical quality control, we surely understand that you need to ensure your products maintain the highest standards. By certifying our design, production and distribution processes, medical device quality management proves to regulators and you that our medical products are all of the highest standard – thereby fostering trust and boosting your reputation.

TBelow are some of our quality control system certificates.